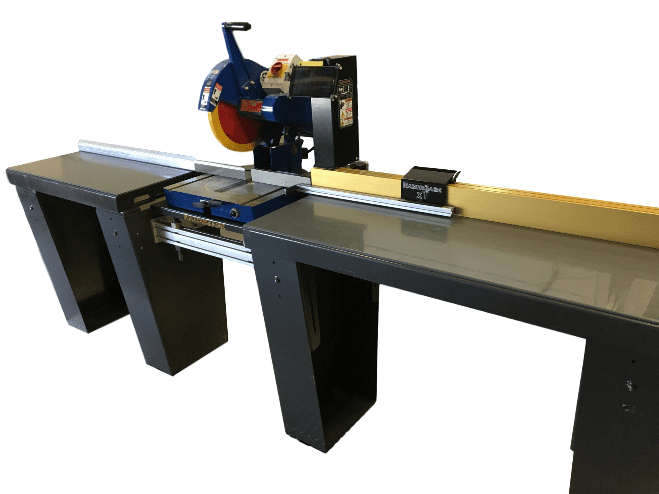

In 2025, woodworking and construction practices are evolving with the integration of perfection technology. One of the most poignant advancements is the use of a Digital miter saw measuring system. This invention has converted how professionals and potterers cut wood, essence, and other accoutrements by perfecting delicacy, effectiveness, and trustability. Unlike traditional measuring styles, this system integrates digital technology to ensure every cut is harmonious and exact, reducing the periphery of error that frequently comes with homemade dimensions.

Precision Through Digital Readouts

Traditional miter sayings calculate heavily on homemade needles, protractors, and tape recording measures, which can be prone to mortal error. With a digital measuring system, druggies profit from clear digital readouts that display precise angles and lengths in real time. This eliminates the guesswork associated with interpreting analog scales and allows for further exact cuts, which is pivotal in systems where small diversions can beget significant problems in alignment or finishing.

Thickness Across Repeated Cuts

One of the topmost challenges in woodworking is maintaining thickness when producing multiple pieces of the same size or angle. Homemade measures frequently lead to small differences that accumulate over time. A digital system ensures that each cut matches the former one precisely. By locking in the dimension digitally, drivers can produce an invariant corridor, which is especially precious in cabinetry, flooring, or large- scale construction where uniformity is essential.

Effectiveness in Complex Angles

Cutting complex or composite angles has always been a test of skill and tolerance. With a digital system, the process becomes more effective because the exact angle is displayed on- screen, and the stoner can acclimate the saw to match that reading impeccably. This reduces the trial- and- error process that frequently consumes time and accoutrements , while icing angles fit together without gaps. In 2025, as designs come more intricate, this effectiveness has become decreasingly important.

Reducing Material Waste

delicacy is directly tied to material operation. Small miscalculations in dimension can lead to wasted wood, essence, or other expensive accoutrements . The digital system reduces this threat by furnishing precise readings before and during the slice process. Over the span of a design, this translates to significant cost savings and further sustainable practices. With sustainability getting a major precedence in 2025, minimizing waste is not only a profitable advantage but also an environmental bone .

Enhancing Safety for Drivers

delicacy and safety frequently go hand in hand. When drivers have to make smaller homemade adaptations and smaller test cuts, their hands remain further from the blade, reducing the threat of accidents. In addition, digital readouts reduce the need to lean close to the saw or make repeated recalibrations, both of which can produce unsafe conditions. The digital approach helps produce a safer work terrain while perfecting delicacy at the same time.

Conforming to Technological Integration

In 2025, numerous shops and job spots are incorporating smart tools and connected systems. Digital measuring technology integrates well with these setups. Some systems can connect with software for design layouts, allowing direct input of measures into the saw for automatic estimation. This not only improves delicacy but also aligns with ultramodern digital workflows where every part of a design, from design to prosecution, is connected.

Streamlining Professional Workflows

For professionals working under tight deadlines, time saved is as precious as delicacy gained. A digital system streamlines the workflow by barring homemade double- checking and remeasuring. systems that formerly needed multiple corrections can now be completed in a smaller way. In competitive diligence where effectiveness determines profitability, these time savings can make a considerable difference without compromising quality.

Meeting Higher Industry Norms

As diligence evolves, so do prospects for perfection and quality. In construction, cabinetry, and cabinetwork- timber, the forbearance for error is shrinking. Guests and inspectors anticipate advanced norms, and a digital system helps meet those prospects constantly. The capability to demonstrate precise measures with digital evidence also provides lesser credibility and professionalism in the eyes of guests and collaborators.

Supporting Both Professionals and potterers

While digital systems are frequently associated with professional surroundings, they also give significant benefits for potterers and learners. Those new to woodworking or construction frequently struggle with dimension delicacy, and a digital display reduces the literacy wind. By giving clear, easy- to- read information, potterers can achieve professional- position results more snappily. In 2025, as further people pursue do- it- yourself systems, this availability is helping expand the reach of advanced tools.

Conclusion

The elaboration of saw technology has readdressed delicacy in woodworking and construction. By introducing digital perfection, thickness, safety, and effectiveness, a digital miter saw measuring system has become a foundation of ultramodern shops in 2025. From reducing waste to meeting the loftiest assiduity norms, it supports both professionals and suckers in achieving better results. As technology continues to shape the future of artificers, tools like these are setting the stage for lesser invention, proving that optimising saws is n’t only about cuttingfasterly but also about cutting smarter and more directly.