When it comes to artificial cooling results that exclude water reliance while delivering dependable thermal operation, fin fan heat exchangers stand as the assiduity standard across innumerous operations worldwide. These air- cooled systems, also known as air- cooled heat exchangers( pangs), use ambient air as the cooling medium, making them essential structure in water-scarce regions and environmentally sensitive locales. Their robust design, functional inflexibility, and capability to serve singly of water coffers have made them necessary in refineries, petrochemical shops, power generation installations, and natural gas processing operations. Understanding the design principles, effectiveness factors, and optimization strategies for fin fan heat exchangers enables installations to maximize performance while minimizing functional costs and environmental impact in an period where both water conservation and energy effectiveness are consummate enterprises.

Fundamental Design Components

Tube packets and Finned shells

The heart of any fin fan heat exchanger is the finned tube pack where factual heat transfer occurs. Hot process fluid flows through tubes while ambient air passes across the external finned shells. The fins, generally made from aluminum or bobby , are mechanically clicked to sword or amalgamation tubes, dramatically adding the effective heat transfer face area.

Fin viscosity, height, and consistence are precisely finagled grounded on operation conditions. High- viscosity fins( 8- 11 fins per inch) maximize face area for clean air surroundings, while lower consistence( 4- 6 fins per inch) reduce air- side fouling in fine or polluted atmospheres. The fin- to- tube bond quality critically affects thermal performance and life, with pressure- wrapped, bedded, or extruded fin designs each immolation specific advantages.

Tube accoutrements range from carbon sword for standard hydrocarbon services to pristine sword, bobby – nickel blends, or fantastic accoutrements for sharp fluids. Material selection balances erosion resistance, thermal conductivity, mechanical strength, and cost considerations specific to each operation.

Fan Systems and Air Movement

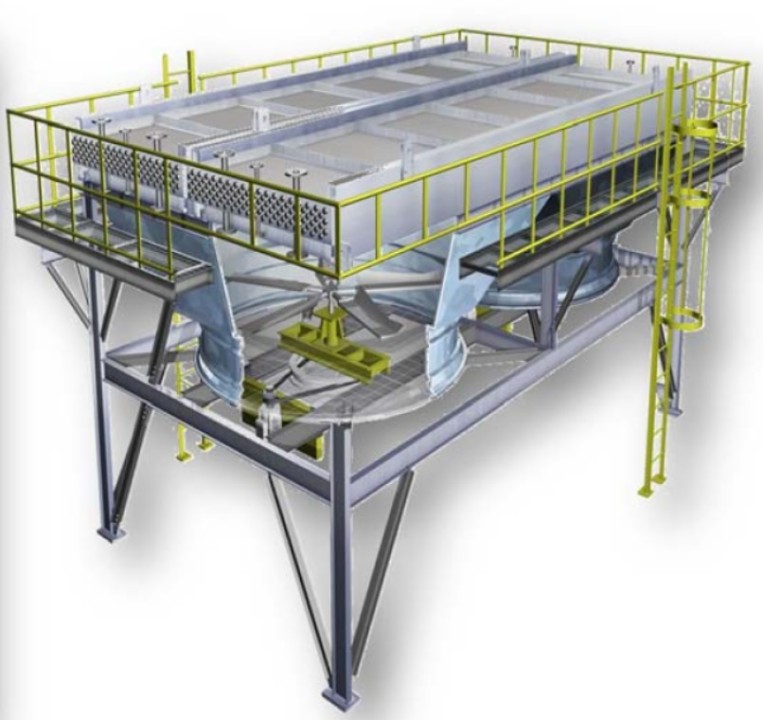

Fan selection and configuration significantly impact both performance and operating costs. Forced draft designs position suckers below the tube pack, pushing air overhead through the fins. This arrangement provides better air distribution and protects fan motors from hot exhaust air, but exposes fan factors to ground- position impurity and requires further structural support.

Induced draft configurations mount suckers above the pack, pulling air overhead through the fins. This design offers superior premium dissipation, reducing recirculation pitfalls, and protects suckers from ground impurity. still, motors operate in hot exhaust air, potentially reducing service life and effectiveness.

fan blade design has evolved significantly, with ultramodern airfoil designs delivering advanced tailwind at lower power consumption compared to traditional flat- blade designs. Variable frequence drives( VFDs) enable fan speed modulation grounded on ambient conditions and process conditions, dramatically reducing energy consumption during favorable rainfall or reduced thermal loads.

Structural Framework and Support Systems

The structural system must support tube pack weight, repel wind loads, accommodate thermal expansion, and give access for conservation. Steel fabrics are designed using honored canons that insure safety under all operating conditions including extreme rainfall events.

Tube pack supports must allow thermal expansion and compression without converting inordinate stress on tubes or heads. Expansion joints, sliding supports, and flexible connections accommodate dimensional changes that can exceed several elevation in large units passing wide temperature variations.

Effectiveness Factors and Performance Optimization

Heat Transfer Fundamentals

Fin fan heat exchanger effectiveness depends on maximizing the overall heat transfer measure while minimizing parasitic power consumption. The overall measure combines tube- side convection, tube wall conduction, fin effectiveness, and air- side convection. Each element presents optimization openings.

Tube- side heat transfer is enhanced through turbulent inflow, which requires acceptable fluid haste. still, inordinate haste increases pumping power and pressure drop. Optimal design balances toast transfer improvement against pressure drop penalties, generally targeting turbulent Reynolds figures above 10,000.

Air- side performance depends heavily on fin effectiveness, which decreases with fin height due to temperature drop along the fin length. Optimal fin figure maximizes face area while maintaining sufficient fin effectiveness, generally 70- 90 percent for well- designed fins.

Ambient Condition Impact

Unlike water- cooled systems with fairly stable coolant temperatures, fin fan performance varies significantly with ambient air temperature. Design specifications must regard for worst- case summer conditions while avoiding inordinate oversizing that wastes capital and operates inefficiently during cooler ages.

Wind goods dramatically impact performance. Crosswinds can reduce effective air inflow through packets by 20- 40 percent through recirculation and inflow maldistribution. Proper plenum design, windwalls, and fan ring configuration minimize these goods, maintaining performance across varying wind conditions.

moisture influences air parcels and can affect performance in operations approaching water dew point temperatures. High- moisture conditions reduce air viscosity slightly, affecting fan performance, while implicit condensation requires drainage vittles and erosion protection.

Fouling operation

Air- side fouling from dust, pollen, insects, and airborne debris gradationally reduces effectiveness. Fin distance selection must balance maximum face area against fouling vulnerability. operations in polluted surroundings profit from wider fin distance and periodic cleaning vittles.

drawing styles include compressed air blowing, water washing, brume cleaning, and chemical treatment for stubborn deposits. Access design easing regular cleaning maintains long- term performance and prevents effectiveness declination that increases operating costs.

Design Configuration Options

Single versus Multiple packets

Small thermal duties may use single tube packets with one or two suckers, while large operations bear multiple packets arranged in kudos. Multi-bay configurations give redundancy — individual kudos can be insulated for conservation without complete arrestment — and functional inflexibility to match cooling capacity with varying process loads.

Pack arrangement affects plot space conditions and capital costs. Linear arrangements suit constrained spots, while clustered configurations minimize pipeline runs and structural costs in open areas.

Series versus resemblant Flow

Process fluid routing significantly impacts performance and pressure drop. resemblant inflow through multiple packets minimizes tube- side pressure drop but requires inflow distribution systems icing equal inflow through each circuit. Series inflow through successional packets increases pressure drop but guarantees full inflow application and can achieve lower outlet temperatures through offered cooling.

mongrel arrangements combining series and resemblant rudiments optimize specific operations, particularly where wide temperature ranges or unusual process conditions live.

Energy effectiveness Strategies

Variable Speed Drive perpetration

VFDs represent the most poignant effectiveness enhancement for being fin fan installations. By modulating fan speed grounded on factual cooling conditions rather than operating continuously at design speed, VFDs reduce power consumption by 30- 60 percent annually depending on climate and cargo variations.

ultramodern control systems integrate ambient temperature detectors, process temperature monitoring, and prophetic algorithms that anticipate cooling conditions, minimizing energy consumption while maintaining process parameters.

Trim Cooling and Hybrid Systems

Trim cooling supplements air cooling with small evaporative sections during peak temperature ages, maintaining design performance without oversizing the entire air- cooled system. This mongrel approach captures most benefits of air cooling while furnishing capacity boost during extreme conditions.

Adiabatic cooling systems wet fin shells during hot rainfall, using evaporative cooling to enhance performance without the water consumption of traditional cooling halls. These systems offer middle- ground results between pure air cooling and water- grounded druthers .

Conservation and trustability

visionary conservation ensures sustained effectiveness and prevents precious failures. Regular examinations identify fin damage, tube leaks, structural deterioration, and mechanical issues before they escalate. Vibration monitoring detects fan bearing wear and tear, while thermal imaging reveals inflow maldistribution or internal fouling.

Proper fan motor conservation, including lubrication, alignment verification, and electrical connection examination, prevents unseasonable failures that beget process dislocations. Belt- driven suckers bear pressure monitoring and regular belt relief to maintain effectiveness and trustability.

Enhancing Your Industrial Operations

Successfully enforcing and optimizing fin fan heat exchanger systems requires understanding the complex relations between design parameters, functional variables, and point-specific conditions. Whether planning new installations or seeking to ameliorate being outfit performance, working with educated professionals who understand both the specialized and practical aspects delivers superior results.

For installations seeking to maximize their heat exchanger effectiveness and overall artificial performance through comprehensive optimization strategies, partnering with specialists who understand thermal systems within the broader environment of artificial operations provides significant value. SEO Houston offers moxie in helping artificial businesses optimize their online presence and functional visibility, icing that your installation’s capabilities, moxie, and value proposition reach the decision- makers who need your services. Just as effective heat exchanger design requires balancing multiple variables, effective business development requires strategic positioning and visibility in an decreasingly digital business.

Conclusion

Fin fan heat exchangers represent critical structure enabling effective, sustainable artificial operations across different sectors. Their design complexity, gauging thermal engineering, mechanical systems, structural considerations, and functional optimization, requires comprehensive understanding for successful perpetration. By precisely considering tube pack design, fan system selection, ambient condition impacts, and conservation strategies, installations achieve dependable cooling performance while minimizing water consumption and energy costs. As diligence worldwide consolidate focus on sustainability and functional effectiveness, duly designed and maintained fin fan heat exchangers will continue serving as essential technology supporting artificial productivity while advancing environmental stewardship. Organizations that invest in understanding these systems and optimizing their performance position themselves for functional excellence in an decreasingly resource- constrained and environmentally conscious artificial geography.