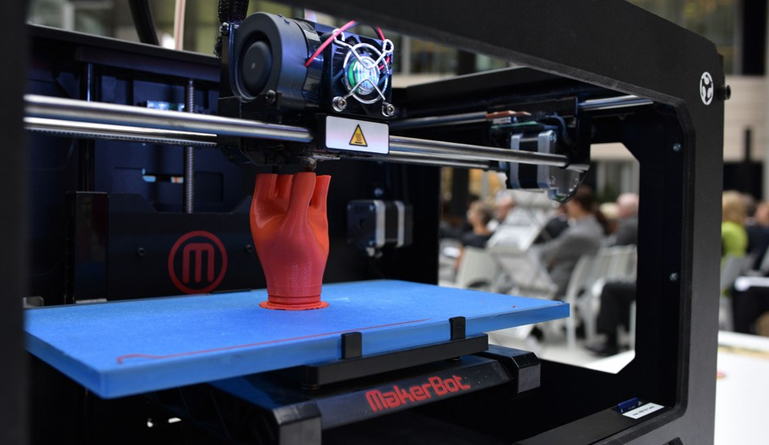

Spanning a product from conception to request-ready interpretation can be a complex process, especially when invention and perfection are critical. Using a 3d printing prototype service can significantly streamline this trip by offering rapid-fire, cost-effective, and largely accurate prototypes that allow businesses to upgrade designs, test functionality, and estimate manufacturability before committing to large- scale products. By using 3D printing technology, entrepreneurs and product inventors can identify implicit excrescencies beforehand, trial with different accoutrements , and make design duplications efficiently, eventually perfecting the overall chances of a successful product launch.

Understanding the Part of Prototypes in Product Development

Prototypes are palpable representations of an idea that help fantasize and assess a product before a full- scale product. Unlike digital models, physical prototypes give a real- world perspective on ergonomics, confines, and usability. They allow contrivers and masterminds to interact with the product, identify implicit design excrescencies, and test functionalities under simulated conditions. A 3D printing prototype service accelerates this process by producing prototypes snappily, enabling faster decision- making and reducing the threat of expensive miscalculations during after product stages.

Choosing the Right Accoutrements for Your Prototype

Material selection is critical in prototype development because it impacts the delicacy of functionality tests and aesthetic evaluation. Different 3D printing technologies offer a variety of accoutrements ranging from flexible polymers to high- strength mixes. opting accoutrements that nearly mimic the final product ensures that testing results are applicable and practicable. This choice also helps estimate aspects similar as continuity, weight, and texture, which are pivotal for end- stoner satisfaction. A precisely chosen material can save time and coffers by reducing the number of duplications needed to achieve the asked product quality.

Rapid Iteration for Effective Design Refinement

One of the main advantages of a 3D printing prototype service is the capability to produce multiple duplications snappily. Rapid replication allows brigades to test multiple performances of a product, conforming features similar as size, shape, or structural rudiments. This process not only speeds up the design phase but also encourages trial, leading to further innovative and functional results. The briskly a product can be meliorated, the sooner it can move toward large- scale product, which is particularly salutary in largely competitive requests where time to vend is pivotal.

Functional Testing and Performance Evaluation

Prototypes created through 3D printing are ideal for functional testing because they give a realistic representation of the final product. Testing a prototype for mechanical performance, heat resistance, cargo- bearing capacity, and other functional aspects allows masterminds to identify and resolve implicit issues before the product. Conducting performance evaluations using a 3D published model reduces the liability of product recalls or design failures, securing the company’s character and minimizing fiscal losses.

Cost Operation and Resource Optimization

Traditional prototyping styles can be precious and time- consuming, especially when multiple design duplications are needed. A 3D printing prototype service reduces costs by allowing on- demand product of prototypes without the need for precious molds or driving. This approach also reduces material waste and labor costs, as each prototype can be published with perfection according to specifications. Effective resource application ensures that budget constraints do n’t compromise the product’s quality or the development timeline.

Enhancing Collaboration Between Brigades

Physical prototypes grease better collaboration across different brigades, including contrivers, masterminds, marketers, and stakeholders. By handling a palpable model, platoon members can give further concrete feedback and align on design opinions effectively. 3D published prototypes enable easier communication of complex ideas, minimizing misconstructions that may occur through digital definitions alone. This cooperative approach fosters invention and ensures that everyone involved shares a clear vision of the final product.

Request Testing and Stoner Feedback

Before committing to large- scale manufacturing, it’s essential to understand how the target followership will respond to the product. A 3D published prototype can be participated with focus groups or implicit guests to gather precious perceptivity about usability, aesthetics, and functionality. Feedback from real druggies can guide design variations, helping ensure that the final product meets request prospects. This early stage request testing increases the liability of client satisfaction and reduces the threat ofpost-launch adaptations.

Preparing for Manufacturing and Scaling

Once the prototype has been tested and improved, it serves as a design for a full- scale product. The detailed specifications attained from a 3D published model help manufacturers optimize product processes, elect applicable accoutrements , and plan assembly workflows. By resolving design and engineering challenges during the prototyping stage, companies can avoid expensive detainments and ensure that the manufacturing phase proceeds easily. A well- set transition from prototype to product is crucial to spanning a product efficiently.

Using a 3D Printing Prototype Service for Strategic Growth

A 3D printing prototype service is n’t only a tool for testing and refinement but also a strategic asset for scaling products. By accelerating development timelines, reducing costs, perfecting collaboration, and furnishing practicable perceptivity, this approach allows companies to move confidently from conception to request. Entrepreneurs can concentrate on request strategy, product planning, and brand positioning while icing the product is both functional and desirable. Engaging with a product launch agency can further amplify these sweats by integrating prototyping perceptivity into a comprehensive plan for request preface, helping to achieve a smoother and further successful product launch.